Volume 3, Number 7 -

July 1998

Journal of the Home Metal Shop Club of

Houston, Texas

See back page for meeting information.

President - George Carlson, V. Pres.- J.D. Wise, Treasurer - Gordon Lawson

Secretary - Keith Mitchell, Editor - Robert Travers , Email

rtravers@enron.com

Notes from the President

June is election month and I am happy to say that we now have a new set of officers for the next year. I just want to say how pleased I was at the last meetings turnout. Also I want to thank all of those who volunteered to run for office. Participation is the key to the success of any club such as ours. In fact, boosting member participation will be my priority for the next year.

In addition to continuing the excellent monthly presentations already in place, we will be adding a few other programs that will help spur members into action. The first is the Monthly Challenge. Every month the members will be challenged to build a project. The assignment will be very ambiguous in nature. This is to allow members to work at their own level with the materials and tools they have on hand. Don't mistake this as a contest. Because of the deliberately ambiguous nature of the assignment, it would be hard to compare projects. The purpose is to give members an excuse to get out in the shop and make chips. Most assignments will allow the use of machining, foundry, sheet metal, blacksmithing, and even woodworking. Something for everyone.

For example, the assignment for July is to Make A Hammer. It doesn't matter what kind of hammer. If you don't own any machine tools, tie a rock to a stick and call it "Traditional". If you are a super designer and machinist, bring in a shop made pneumatic nail-gun. I suspect most projects will fall somewhere in between. The point is, do what you can. If you have problems getting a thread cut properly, a bad finish, or have a welding problem, bring it to the meeting. Maybe someone could give you some tips so you can do it better next time. Take a look though the tool catalogs for hammer ideas. Starrett makes a small hammer with a magnifying glass. Dean Eicher has a South Bend training manual that has a neat little hammer with a center punch stored in the handle. The possibilities are endless. One bit of advise, start off building something simple. Don't let "feature creep" leave you with nothing but good ideas and no product. Each month we will have a similar assignment.

A universal problem HSM's have is availability of materials. As a club, it seems there ought to be something we can do about this. Jim Anderson has volunteered to become Materials Coordinator for our club. Call Jim for information on where to find material, and let him know what kind of material you generally need. At some point in the future we will start acquiring material to stock for use by club members working on projects. At first we will do some begging for scrap at local suppliers. If interest is high enough, we may make some purchases of material to be resold to club members, probably at about 10% above cost to cover scrap. More about this later. Call Jim at (713) 864-8978 for details and suggestions.

October is swap meet time. George Edwards has volunteered to plan and manage the 2nd Annual Swap Meet and Junk Dump. I know that October seems pretty far off, but it will be here before you know it. Start digging out those goodies for the meet.

David Whittaker is our new librarian. See David for checking out and returning videos and books.

In order to streamline our meetings, the majority of the business will be conducted in a business meeting prior to the normal monthly get together. The officers, and who ever else that would like to join us, will meet at the Barbecue Inn at 11:30 on the day of the meeting. Barbecue Inn is located at Crosstimbers and Yale, about one mile east of the library. Everyone who would like to introduce some ideas or comments is invited to join us for lunch. The goal is to reduce the business part of the meetings to 10 minutes or less. This will give us more time to talk about making chips.

Well that's it for this month, don't forget the Monthly Challenge. See you at the next meeting

Some Shop Tips

by George Carlson

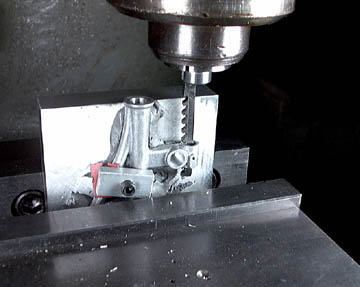

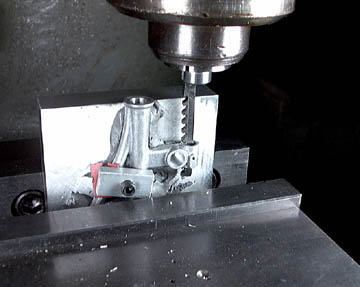

When I was building a small model drill press I had to cut a slot in the top casting to clear the rack for the quill. The slot was to be 0.125" wide and about 0.1" deep. There were two problems with this. The hole for the quill was only 0.25" in diameter, too small to use a normal broach guide. Also, the top of the casting overhangs the quill. This meant the broaching operation was essentially going to have to be treated as a "blind" operation. There wasn't enough clearance between the quill hole and the top of the casting for the broach to pass all the way through.

The broach was ground down flush with the guide

Photo of the broach in use

Looking through my assortment of broaches I found a 1/8" broach that I had broken some time in the past. (I can't blame that on the dog). I placed the broach in a 3/8" guide and ground back the part of the broach the stuck out above the guide. I then chucked the guide in a collet and used my milling machine quill as a "shaper" and cut the required slot. Moving the quill up and down in a sawing motion as I advanced the table to the desired depth of cut Worked out fine.

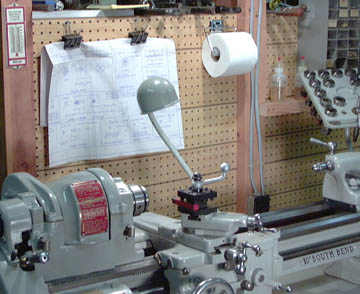

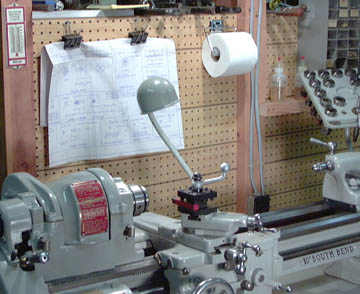

See anything in this picture that doesn't belong?

If you said the roll of toilet paper, you'd be wrong. For quick clean-ups, wiping off chips, and polishing, it can't be beat. Having the roll handy will help prevent the temptation of wiping off a workpiece in the lathe with a rag. This is a very dangerous thing to do because a moving chuck can grab the rag and pull your hand into the lathe. A paper towel or a piece of toilet paper is much safer. The little squares of toilet paper are not as wasteful as large paper towels. The little squares of toilet paper and some duct-tape also make good shop-made Band-Aids for those little shop-made boo-boos. :)

The Rifling Attachment, Part Deux

A Rifling Cutter

by George King

Gunsmithing texts describe hook and scraper cutters. I have had no success with either.

Then, one day while hack sawing a piece of steel, I was smitten with inspiration: If I could cut the inside of a barrel with the ease with which I was then cutting, rifling would be easy.

Reciprocating power hacksaw blades consist of a narrow tooth section of high speed steel brazed to a machinery steel backing that can be easily worked. I you can come by a discarded blade, there is always about an inch of virgin teeth on each end. Any method for holding a short section of teeth and provide a means for successively raising the teeth will suffice. The drawing is for a .58 caliper barrel. For smaller bores, rather than a crimp plat, I cut slots in the saw blade backing for the clamping screws.

With the depicted cutter, milling the recesses will remove 90 of the feed screw holes, so these must be drilled and tapped before milling.

Being primarily interested in black powder barrels, I've never attempted anything under .45 caliber.