|

Making

a Machinist's Jack |

Often the new owner of a machine tool such as a lathe is hesitant to use the tool because he fears making a mistake and either injuring himself or breaking the tool. It is the purpose of this tutorial to show such a new user that he can use the lathe to produce a useful object without creating some sort of catastrophe.

The

machinist’s jack shown above is a simple project, requiring several

basic techniques to produce it. Materials required are:

a one inch length of ¾-in hexagonal or round steel

rod, Two 5/16 – 24 nuts, and a 1-in long 5/16

- 24 machine screw. A few tools are required.

In addition to a lathe, they include: 3-jaw chuck, tailstock

drill chuck, # 4 center drill, 5/16–24 tap with matching

tap drill, lathe cutting bit, hacksaw and a protractor.

The

machinist’s jack shown above is a simple project, requiring several

basic techniques to produce it. Materials required are:

a one inch length of ¾-in hexagonal or round steel

rod, Two 5/16 – 24 nuts, and a 1-in long 5/16

- 24 machine screw. A few tools are required.

In addition to a lathe, they include: 3-jaw chuck, tailstock

drill chuck, # 4 center drill, 5/16–24 tap with matching

tap drill, lathe cutting bit, hacksaw and a protractor.

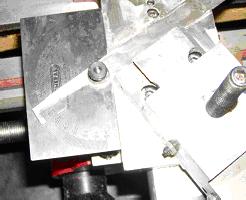

The

first set the cross slide to 30 degrees. This allows you

to determine the depth of cut easily using the calibrations

on the compound dial. On my lathe, each mark is 2 thousands

of an inch. Because we are moving the cutting tool along the

hypotenuse of a 30-degree right triangle, each mark becomes

1 thousandth. The body of the jack is chucked up in the 3-jaw

chuck and turned at the lowest speed. The compound slide

is advanced until it just kisses the face of the jack body,

then the cross slide is advanced until the tool bit reaches

the center of the workpiece. The cross slide is then retracted

until the bit is no longer in contact with the workpiece. Advance

the compound slide about 30 thousandths and repeat the cutting

operation by advancing the cross slide to the center and back.

Repeat this operations until the face of the jack is smooth. Then,

continue the smoothing process by taking smaller cuts: at 20

thou, at 10 thou, and several at 5 thou until the desired smoothness

is achieved.

The

first set the cross slide to 30 degrees. This allows you

to determine the depth of cut easily using the calibrations

on the compound dial. On my lathe, each mark is 2 thousands

of an inch. Because we are moving the cutting tool along the

hypotenuse of a 30-degree right triangle, each mark becomes

1 thousandth. The body of the jack is chucked up in the 3-jaw

chuck and turned at the lowest speed. The compound slide

is advanced until it just kisses the face of the jack body,

then the cross slide is advanced until the tool bit reaches

the center of the workpiece. The cross slide is then retracted

until the bit is no longer in contact with the workpiece. Advance

the compound slide about 30 thousandths and repeat the cutting

operation by advancing the cross slide to the center and back.

Repeat this operations until the face of the jack is smooth. Then,

continue the smoothing process by taking smaller cuts: at 20

thou, at 10 thou, and several at 5 thou until the desired smoothness

is achieved.

This operation is known as facing off the

workpiece.

This operation is known as facing off the

workpiece.

Reverse the workpiece in the chuck and face off the other end. Leave the workpiece in the chuck, and put the drill chuck in the tailstock. Chuck up the center drill and proceed to drill the workpiece by advancing the tailstock chuck into the turning workpiece with the lathe running at slow speed. By starting the hole with a center drill, the drill is fed properly to the center of the stock.

Once

the center drill has cut into the workpiece to the depth of

the V-shaped tip, remove the center drill and replace it with

the tap drill bit. You may now drill the center hole, by running

the lathe at slow speed and advancing the drill by turning the

tailstock advance handle. It may be necessary to reposition

the tailstock in order to complete the hole. The advantage of

drilling the hole on the lathe is that it is drilled exactly

on the center axis of the workpiece.

Once

the center drill has cut into the workpiece to the depth of

the V-shaped tip, remove the center drill and replace it with

the tap drill bit. You may now drill the center hole, by running

the lathe at slow speed and advancing the drill by turning the

tailstock advance handle. It may be necessary to reposition

the tailstock in order to complete the hole. The advantage of

drilling the hole on the lathe is that it is drilled exactly

on the center axis of the workpiece.

Once

the hole has been completed, it is time for the most tedious

operation in this project, tapping the center hole. This

operation is done entirely by hand, with the lathe used only

to hold the workpiece and the tap. The tap is chucked up in

the tailstock, that is advanced to the center hole in the

workpiece. Even the slowest lathe is too fast to be used for

power taping. Instead, the three-jaw chuck is turned by hand,

while the tap is slowly advanced into the workpiece. Use tapping

or cutting fluid to make the process easier. Be sure to back

out the chuck about every half turn to clear the chips. At times

turning the three jaw becomes too difficult and the chuck wrench

may be used as a lever to turn the chuck.

Once

the hole has been completed, it is time for the most tedious

operation in this project, tapping the center hole. This

operation is done entirely by hand, with the lathe used only

to hold the workpiece and the tap. The tap is chucked up in

the tailstock, that is advanced to the center hole in the

workpiece. Even the slowest lathe is too fast to be used for

power taping. Instead, the three-jaw chuck is turned by hand,

while the tap is slowly advanced into the workpiece. Use tapping

or cutting fluid to make the process easier. Be sure to back

out the chuck about every half turn to clear the chips. At times

turning the three jaw becomes too difficult and the chuck wrench

may be used as a lever to turn the chuck.

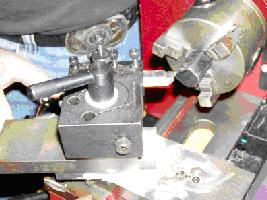

After

the complete center hole is tapped, you have a machinist jack.

This jack, while usable is quite crude. I like to spiff

it up a little, and this gives you the opportunity to learn

a couple more techniques. The photos show a screw in the center

hole, and a jam nut on the screw. Align the faces of the

nut and screw and chuck them in the three-jaw chuck so that

the jam nut is at the end of the jaws. Screw the body of the

jack onto the machine screw until it reaches the end of the

jaws.

After

the complete center hole is tapped, you have a machinist jack.

This jack, while usable is quite crude. I like to spiff

it up a little, and this gives you the opportunity to learn

a couple more techniques. The photos show a screw in the center

hole, and a jam nut on the screw. Align the faces of the

nut and screw and chuck them in the three-jaw chuck so that

the jam nut is at the end of the jaws. Screw the body of the

jack onto the machine screw until it reaches the end of the

jaws.

Reset

the angle of the compound slide to 115 degrees to the cross

slide. Mount a left hand facing tool in the tool post and proceed

to cut a taper by moving in the cross slide until the too bit

just kisses the work piece, and then advancing and retracting

the compound to cut the taper. Advance the cross slide about

15 thou and repeat the cutting operation. Notice that unlike

facing, the cross slide is used to set the depth of cut and

the compound slide controls the actual cutting movement.

At first, the cut will be short, but after a few passes, the

taper will appear and can be cut to the desired length. In

this case, the taper should be cut until the top of the jack

is about the diameter of the head of the screw you are using.

Reset

the angle of the compound slide to 115 degrees to the cross

slide. Mount a left hand facing tool in the tool post and proceed

to cut a taper by moving in the cross slide until the too bit

just kisses the work piece, and then advancing and retracting

the compound to cut the taper. Advance the cross slide about

15 thou and repeat the cutting operation. Notice that unlike

facing, the cross slide is used to set the depth of cut and

the compound slide controls the actual cutting movement.

At first, the cut will be short, but after a few passes, the

taper will appear and can be cut to the desired length. In

this case, the taper should be cut until the top of the jack

is about the diameter of the head of the screw you are using.

After cutting

the taper, the next step is to make another tool, a clamp nut,

by holding a nut in a vice and cutting half way across it with

a hacksaw. The clamp nut is threaded onto the machine screw,

and then the clamp nut is chucked in the three jaw chuck, leaving

the head of the machine screw exposed so the it may be faced

off. The slit in the side of this nut allows it to compress,

providing a strong non-damaging grip on the bolt in

the three jaw chuck. The compound slide is reset to 30

degrees, and the head of the machine screw is faced off in the

same way and the ends of the jack. This completes the operation

except for the final assembly, which consists of screwing on

the jam nut, screwing the machine screw into the head and showing

off your new tool.

After cutting

the taper, the next step is to make another tool, a clamp nut,

by holding a nut in a vice and cutting half way across it with

a hacksaw. The clamp nut is threaded onto the machine screw,

and then the clamp nut is chucked in the three jaw chuck, leaving

the head of the machine screw exposed so the it may be faced

off. The slit in the side of this nut allows it to compress,

providing a strong non-damaging grip on the bolt in

the three jaw chuck. The compound slide is reset to 30

degrees, and the head of the machine screw is faced off in the

same way and the ends of the jack. This completes the operation

except for the final assembly, which consists of screwing on

the jam nut, screwing the machine screw into the head and showing

off your new tool.