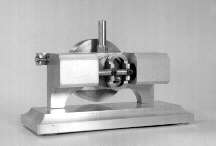

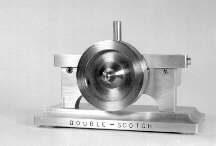

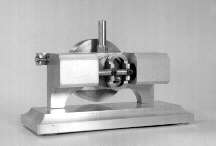

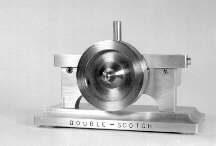

The Double Scotch

In browsing through my copy of Elmer's Engines, by Elmer Verburg, I ran

across a steam engine he named "Scotty". This engine used a scotch

yoke to translate the reciprocating motion, of the piston to the rotary motion

of the output shaft. The engine had a one single acting horizontal cylinder. A

sliding support was necessary at the opposite end of the connecting rod from

the piston. Another feature was that the crank-shaft was used as a rotary

valve. A neat little engine, but we need MORE POWER. Instead of using a support

for the connecting rod, this design uses another piston and cylinder. In place

of the rotary valve, my design uses a spool valve driven by another scotch

yoke. Two scotch yokes, one converting reciprocating to rotary, the second

convert rotary to reciprocating, hence the name "Double Scotch".

The drawings are in Adobe Acrobat 3.0 format. This is to provide the builder

with high quality drawings with minimal download time. Acrobat also preserves

the vector base information so that the drawings can be enlarged as much as

desired without losing resolution. If you do not have Acrobat 3.0, download it

for free right here.

The engine is very smooth and will run on air as low as 1 PSI. Operation of

the engine is simple. Air or steam is introduced through the INLET at the top

center of the engine. The 3/16" passage-way through the FRAME ducts the

steam to valves at each end of the engine. The disk of a valve either directs

steam into the cylinder from the passage way, or releases steam from the

cylinder into the atmosphere, at each end of the engine. Timing for the valve

is generated by an eccentric on the backside of the flywheel.

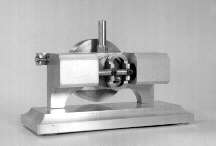

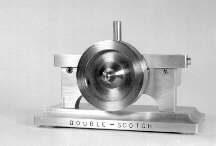

Most parts of the "Double Scotch" are made from 6061 Aluminum. The

ball bearing is quite small, 3/8" diameter with a 1/8" bore. A

bushing made from bronze or brass would also work well. Notes for the

construction of the "Double Scotch" are given below:

Construction Notes

- MAIN BEARING - Turn from brass or bronze. Bore or ream to fit

available 1/4" drill rod.

- CYLINDERS - Two cylinders are made as opposites. The cylinder for

the left side (facing the cylinders) is shown in the drawing. The cylinders are

made from 6061 aluminum. The bore can be drilled then finished with an end

cutting endmill to a depth of 1.062". The diameter is not real critical

because the piston can be fitted later. The hole must be smooth, round, and

have straight sides. The small hole used to allow steam into the top of the

cylinder is first drill with a 3/32" drill bit to a depth about

0.030" full diameter. The 1/16" hole can now be drilled at an angle

suitable to come through into the cylinder, just about center. This is not too

critical. The two 4-40 threaded holes are drilled and tapped to a depth of

3/8".

- PISTONS - The pistons are turned from brass. They should be made

after the CYLINDERS so that they may be made to fit. About 0.001 to 0.002

undersize is good. Cut a few shallow oil grooves in the outside of the piston

to aid lubrication and sealing.

- CRANKSHAFT - The crank is made in two pieces then silver soldered

together. The disk is made from mild steel, the shaft from drill rod. Make the

disk a little thicker than final size to allow for facing after the silver

soldering.

- FLYWHEEL - The flywheel is made from 2" diameter mild steel.

Because part of the flywheel is the eccentric to operate the valves, it is not

a good idea to use aluminum. Face the disk and layout the center of the

flywheel and the eccentric. Place the blank in a 4-jaw and adjust to make the

eccentric center runs true as well as the face. Cut the eccentric 0.500"

diameter and .094 wide. Set the blank so the flywheel center runs true as well

as the face. Cut the 0.031 step then drill and ream the 1/4" hole. Reverse

the blank and make the cuts on the front side of the flywheel. These cuts are

mainly cosmetic. Drill and tap the 6-32 hole for the setscrew.

- FRAME - The frame is made from 3/8 aluminum. The steam passage

should be carefully drilled from each end with an under size drill bit, then

reamed to 3/16 all the way through. The hole for the inlet is drilled and

tapped to a convenient size. I used 1/4-32. A fine thread is necessary, 10-32

would work OK. Drill the other holes as indicated, be careful to locate them

accurately.

- MAIN SCOTCH YOKE - This is a neat little part made from aluminum.

The profile on the outside is not critical, but the inside dimensions and the

shaft mounting seat are critical. The two 2-56 holes are drilled and tapped

through.

- VALVE YOKE - Start out with a piece of aluminum 3/8" x 4"

x 1 1/32" and cut away 90% of it. One tip: cut the part to thickness

first, then cut the oval cutout, then cut the profile on the outside.

- PISTON ROD - Turn from 3/16 mild steel. Spot face the two holes for

#2 socket head screws.

- SPOOL VALVE ASSEMBLY - This could be made from the solid, but it is

much easier to make it up from a piece of 1/16" brazing rod and some small

disks. Make the disks from brass 3/16" diameter, 3/32" thick, with a

1/16" hole in the center. Measure your 1/16 rod, mine was a bit smaller,

so I drilled a little smaller hole in the disks. Use a piece of 1/16"

brazing rod a little longer than what is needed. Soft solder one of the inside

disks into place. Mark the shaft 3.125" from the first disk and solder the

second disk. Use the VALVE YOKE to hold the 1/16" rod while the two end

disks are soldered in place. The will help assure a snug fit from the yoke to

the valves.

- CRANK SCREW - Make this small screw from drill rod or mild steel.

Cut the 0.125" shoulder so that it will be a light press fit into the ball

bearing. If you do not have a bearing, make one from brass on bronze. The

dimensions are: 0.375" diameter, 0.156" thick, bore 0.125"+ for

rolling fit.

Assembly

- Assembly and fit-up are pretty simple. The drawings of the completed engine

should be helpful.

- To make sure the cylinders match-up try the following trick. Take a short

length of 1/2" drill rod, say 3"long. Slide the two cylinders over

the drill rod, and lap the sides that mount against the frame on a piece of 400

grit SC paper with a little oil for lubrication. This will help assure that the

pistons will not bind when the assembly is put together. Also, leaving the

pistons slightly loose on the piston rod can help if things are not quite

right. Apply Locktight to the threads on the end of the piston rod before

assembly.

- If the ball bearing fits loose on the Crank Screw, or you are using a

bronze bushing, make a small washer 1/4" in diameter and 1/8" bore

for use between the bearing and the crankshaft disk.

- Use 1/4" 2-56 socket head screws to secure the Piston Rod to the Main

Yoke.

- Fasten the Cylinders to the Frame using four 5/8" 4-40 flat head

screws.

- To prevent the Valve Yoke from catching on the end of the Main bearing,

make a washer from 0.005" brass shim stock. The washer should have an O.D.

of 1" and an I.D. of 1/4". Place the washer on top of the main

bearing before the Valve Yoke and Flywheel are installed. The Flywheel requires

a 3/16" 6-32 set screw.

- To set the valve timing, turn the crank until both pistons are in the

center of their travel. Then while holding the Crankshaft still, turn the

Flywheel until the Spool Valve is at it's furthest travel, then lock-down the

setscrew on the Flywheel.

- There are two tapped holes in the bottom of the Frame. These are used to

mount the Double Scotch to a suitable base. I used a 2" x 5" x

3/8" piece of aluminum plate as the base. A 5/8" ball end mill was

used to provide the decorative edge around the top of the base. Two socket head

cap screws, 8-32 x 1/2", were used to hold the engine to the base.

- Break-in the engine using compressed air. Only five to ten PSI should be

required. Use plenty of oil during break-in.

Download drawings

Right click on file name and

select "Save Target As.."

Acrobat Format dscotch.pdf

(111K)

.gif format (2 files) dscotch_assembly.gif

(15K) dscotch_drawing.gif

(91K)

2/4/97