Volume 10, No 1 - January 2005

|

Volume 10, No 1 - January 2005 |

|

|

|

|

|

| President - |

Vice President - |

||

| Treasurer - |

Secretary - |

||

| Webmaster |

Editors - |

||

| Founder - |

SIG Coordinators - |

Statement of Purpose

Membership is open to all those interested in machining metal and tinkering with machines. The club provides a forum for the exchanging of ideas and information. This includes, to a large degree, education in the art of machine tools and practices. Our web site endeavors to bring into the public domain written information that the hobbyist can understand and use. This makes an organization such as this even more important.December Regular Meeting

Collier Library, Houston Texas, December 11, 2004, 1:00 p.m., Chuck West - President, presiding. There were 30 members attending with four guests: Dan Harper, Jim Clark, Tim Bailey, Rob Lucas-Dean.

Business Meeting

Minutes are sent via email or regular mail to club members.

Presentation

Joe Scott showed and discussed some videos. The first video dealt with forging of the M1 machine gun receiver. The second covered various aspects of manufacturing the Johnson Rifle.

Special Interest Groups Activity:

Novice Sig

The novice group discussed types

of drills bits and hole

drilling. They aligned (trammed) the drill press using a dial indicator in

order to determine

the perpendicularity of the table to the spindle's axis. Then they checked the runout of the

chuck. Examples of excessive speed (RPM ) were shown along with correct

speed vs. drill diameter vs. metal type were demonstrated. The need for center punching

and use of pilot

holes was explained. Various drill fixtures and jigs were shown. The group had hands-on

practice feeding drills for optimum drill life using a Teflon block and

measured the drill chip thickness with a micrometer.

The novice group discussed types

of drills bits and hole

drilling. They aligned (trammed) the drill press using a dial indicator in

order to determine

the perpendicularity of the table to the spindle's axis. Then they checked the runout of the

chuck. Examples of excessive speed (RPM ) were shown along with correct

speed vs. drill diameter vs. metal type were demonstrated. The need for center punching

and use of pilot

holes was explained. Various drill fixtures and jigs were shown. The group had hands-on

practice feeding drills for optimum drill life using a Teflon block and

measured the drill chip thickness with a micrometer.

Machinist's notebooks were distributed to the two new novices.

The January meeting will be about sharpening shop tools. Please bring a tool (knife, chisel, screw driver, high speed. lathe tool bit, etc.) that needs sharpening. We will also try to demonstrate a layout procedure using the 6-in. dial caliper with the aid of a video camera and the large TV screen.

CNC Sig

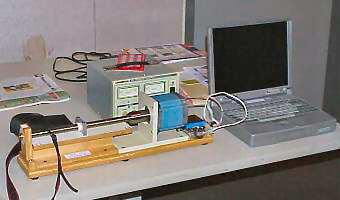

Jan Rowland brought in a show-and-tell setup of a

lead-screw turned by a stepper-motor driven by a famous Gecko drive

directly connected to the printer port of a laptop. With that, it could be

demonstrated how programmed moves could be easily made with home-brew hardware.

Jan Rowland brought in a show-and-tell setup of a

lead-screw turned by a stepper-motor driven by a famous Gecko drive

directly connected to the printer port of a laptop. With that, it could be

demonstrated how programmed moves could be easily made with home-brew hardware.

Show and Tell

Doug Chartier showed a very nice tapping head for his machining center.

Joe Scott showed a tail stock turret and some tap and die holders for it.

Tim Bailey showed a rather impressive hand forged curtain rod end.

Rich Pilcher showed a shop built tail stock live chuck and list of operations for making the adapter and a micrometer stop chamfer tool.

Jan Rowland discussed a density calculation to try to determine the makeup of an unknown material. He also showed a photo of last months knife display.

Joe Scott talked about die drills and tapping a case hardened rifle

receiver.

|

|

|

|

Joe Williams passed around his C-clamp that

was pictured and discussed

in last months news letter. He also showed an old toolbox and its

contents that he recently acquired. |

Tom Moore showed his milk crate dolly he uses for storage. |

Rob Lucas-Dean showed his shop made Propane Burner and asked about

furnace building. |

Dick Kostelnicek showed a commercial shim punch. |

Featured Articles

Measuring Density on the

Cheap

by Dick Kostelnicek and Jan Rowland - HMSC Members

If you have a piece of material, it could be a metal

or wood bar, and you want to determine its specific density, that is the density

relative to water, in order to identify its composition, then read on..

Now, normally you would first have to determine the volume of the bar.

However, measuring volume is often a messy job since you need to submerge the piece under

water and note the amount of water displaced. This can be done with a

graduated cylinder or an overflow tank.

If you have a piece of material, it could be a metal

or wood bar, and you want to determine its specific density, that is the density

relative to water, in order to identify its composition, then read on..

Now, normally you would first have to determine the volume of the bar.

However, measuring volume is often a messy job since you need to submerge the piece under

water and note the amount of water displaced. This can be done with a

graduated cylinder or an overflow tank.

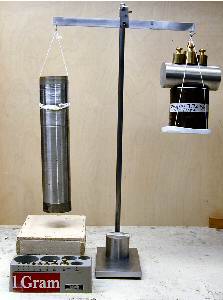

Well, you can get the specific density directly with just a bucket of water, a length of string, and a fish weighing scale. Now, the water in the bucket should be deep enough so that the unknown bar of material will be completely submerged without touching the bottom of the container. It is OK if the bar wants to float so long as the bucket is big enough that the bar can be submerged completely under water with the help of an addition sinker weight.

Method for density greater than 1.0: ( This is where the bar sinks on its own )

Weigh the bar hanging from a string in air ( see upper left

photo ). Call this amount Wa.

Weigh

the bar hanging from the string and completely submerged under water but

not touching the bucket's bottom (see upper right photo ). Call this amount Wb.

Then, the specific density D is given by the formula: D = Wa / (Wa - Wb).

Method for density less than 1.0: ( This is where the bar wants to float )

Get a sinker weight that is just heavy enough to submerge both the unknown bar and the sinker when both are lashed together.

Weigh

the bar alone in air. Call this amount Wa.

Determine the weight of the sinker by

itself under water. Call this amount

Ws.

Finally, lash

the bar and the sinker together and weigh them with both completely

submerged. Call that amount Wt.

Then, the specific density D of the unknown bar is given by the formula: D = Wa / (Wa + Ws - Wt)

Jan Rowland - HMSC Member supplied the photos and constructed

a beam balance using an ultra low friction precision ball bearing for his density

measurements .

Manual Lever

Feed for a Mill-Drill

by Joseph Scott - HMSC Member

I

needed to slot about 100 small fillister head screws on my mill-drill. Cranking

the Y-axis got old and was hurting my wrist, so I made a modification to mill.

Basically, I removed the Y-axis feed screw and installed a wobble stick hand-lever

to move the table for the slotting operation. Later, I took out the X-axis screw so

that the single lever would move the table in any horizontal path like

a joy stick. I will use it in the future to trace 2-D patterns

form original gun parts.

I

needed to slot about 100 small fillister head screws on my mill-drill. Cranking

the Y-axis got old and was hurting my wrist, so I made a modification to mill.

Basically, I removed the Y-axis feed screw and installed a wobble stick hand-lever

to move the table for the slotting operation. Later, I took out the X-axis screw so

that the single lever would move the table in any horizontal path like

a joy stick. I will use it in the future to trace 2-D patterns

form original gun parts.

I did it this way: Drilled 2x1/2-in. channel to clamp on table with an additional hole for a 3/4-in. pipe lever. Clamped a 2x2-in. angle onto the mill's support legs and put a 1/2-in. bolt sticking up to form a pivot point. Removed the Y-axis screw and loosen its gib. Cleaned and oiled slide. Positioned table for depth of screw slot and locked the X-axis slide.

The screw slotting operation is as follows: Lever the table outwards. Install a new screw in the collet. Lever the table backwards for the cut. Reverse the lever. Repeat the operation.

Long ago I think these lever operated machines were called profilers.

More on Shop Air

Shut Off

by George Carlson - Former HMSC Member

I saw your article on using a photocell

to control the compressed air in your shop. I have my compressor mounted

outside in a little lean-to. It's nice, because it doesn't take

up space in the shop, and the insulation in the lean-to cuts the noise

to a whisper. Once, the compressor threw a belt, and the motor ran for

two days. So I had to come up with a fix. I wired a contactor (electrical

relay) in series with the 240VAC to the compressor. The primary or control side

of the contactor is connected to the shop's 110VAC lighting

circuit. So, now the compressor can only run when the shop lights are

on.. a very simple fix that works

quite well.

|

Visit Our Home Page at |

|

Right

click below then select [Save Target As..]

From Netscape select [Save Link As..]

Microsoft

Word version of this newsletter 172 KB