Building a

"Zero-It" Type Indicator Holder

Introduction

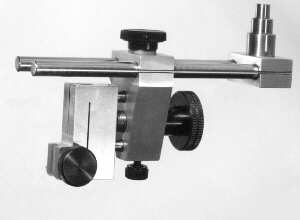

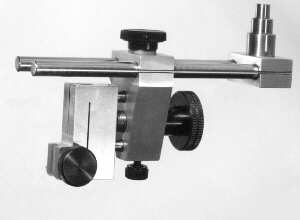

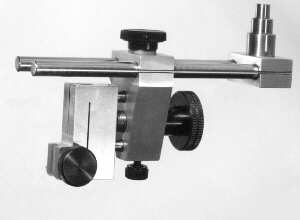

The design of this device is based on the "Zero-It"

holder made by Mitutoyo and others. The holder can be used with

any Test Indicator that has dovetails, or those that have a

.250" diameter top stud. The holder block could be easily

modified for use with indicators such as the Starrett "Last

Word" type, or dovetail adapters can be purchased for these

indicators.

The supplied drawings differ from the photograph in only a few

places. The spindle in the prototype was much shorter. The screw

in the side of the Holder Block is smaller. Also, the main block

in the prototype was 5/8" thick, not 1/2" as in the

final version. Please check your kit to make sure all of the

materials in the list were supplied correctly.

Construction

Construction is not too difficult. There are only a couple of

areas where special attention is required. These are the holes

used for the rods for the course and fine adjust. This is because

even a small amount of misalignment can cause binding in the

mechanism. The instructions detail the use of a dial indicator

for locating the holes to be drilled. If you have a digital

readout, the dial indicator should not be necessary. All holes

should first be started with a center drill, this helps insure

that the hole will be started straight and in the correct

location.

Spindle Block

- Square-up and mill the block to size. 1.125" x

0.625" x 0.500 (ref)

- Clamp block in vise so that the 5/8 side is up.

- Locate the center of the side using your normal

procedure.

- Use an "F" drill bit and drill full diameter

.280" deep.

- Finish the hole using a #7 drill bit.

- Tap the hole 1/4-20.

- Remove the block from the vise and chamfer both the top

and bottom of the hole.

- Put the block back in the vice with the 1/2" side

facing up, 1.125 side aligned with the "X"

axis.

- Locate the center of the block as in #3 above.

- Fasten a dial indicator to the mill such that it can be

used to measure travel on the "X" axis.

- Preset the dial indicator to 0.500", this is the

center of movement.

- Move to the left 0.375" for the first hole. Lock

down the table.

- Center drill, then drill through 15/64"

- 14. Ream the hole to .250" or use a 1/4" drill

bit and carefully drill the hole to size.

- Unlock the table, move right until the indicator reads

0.375" on the other side of center. Lock the table.

- Repeat steps 13 and 14 above.

- Remove the piece and chamfer both ends of the two holes.

- Cut the slot using a bandsaw or hacksaw.

Main Block

- Square-up and mill the block to size. 1.750" x

1.125" x 0.500(ref)

- Clamp the block in the milling vise such that the 1.75 x

1.125 side is facing up, and that the 1.75" side is

aligned with the "X" axis.

- Locate the center of the block in the "Y" axis

(center of the 1.125 dimension), and lock the

"Y" axis.

- Locate the top edge (left hand edge) of the block and

zero the dials on the handwheels. Move to the right

1.125", this is the location of the hole marked

"C". Lock down the table.

- Center drill, then drill through with an "F"

size drill.

- Mount a dial indicator as before with the Spindle Block.

- Unlock the table and move 0.400" to the left. Lock

the table.

- Center drill then drill through with a 11/64" drill

bit.

- Ream the hole to .1875, or use a 3/16 drill bit.

- Check the size of the hole by sliding one of the pieces

of 3/16 drill supplied. It should slide through the hole

without much effort. If it if too tight, try another pass

with the same drill bit, or try another bit.

- Unlock the table, Move to 0.400" on the other side.

Lock the table.

- Repeat steps 8, 9, and 10 above.

- Remove the indicator, unlock the table, and move to

0.250" from the top (left side). Lock the

"X" axis.

- Mount a dial indicator such that movement on the

"Y" axis can be measured.

- Using the "Y" axis, locate and drill the two

0.250" holes in a similar manner as with the Spindle

Block.

- Remove the piece from the vise. Chamfer all holes.

- Mount the piece back in the vise with 1.125 x .5"

side nearest the two .250" holes (the top side), up.

- Locate the center of this side and drill and tap as in 4,

5, and 6 of the Spindle Block. Drill the #7 hole full

diameter to .700"

- Turn the block over in the vise and drill and tap the

6-32 hole for the Fine Adjust Lock Screw.

- Remove the block from the vise and by using magic marker

on Dykem bluing, scribe the lines for the angles to be

cut on the sides of the main block.

- Clamp the block in the vise with one of the cut lines

lined up with the top of a thin parallel placed on top of

the vise jaws.

- Mill off the excess material.

- Do the other side of the block as in 21 and 22 above.

- Knock off any burrs and break sharp corners with a file.

Holder Block

- As in the parts before, square-up and mill the block to

size. 1.500" x 0.975" x 0.500(ref)

- Mark the front of the block, (where the dovetail will be)

with a magic marker.

- Set the block in the milling vise with the 0.975 x

0.500" end to the top. Make sure the block is

sitting square to the vise.

- Locate (0.475" from the side with the mark) and

drill the 1/4" hole through the block from top to

bottom.

- Remove the block from the vise and chamfer both ends of

the hole.

- Place the block back in the vise with the front side (the

side with the mark) down. The long dimension

(1.500") should be aligned with the "X"

axis.

- Find the center of the block on the .500 dimension

("Y" axis). Lock the "Y" axis.

- Locate the top ( left ) edge of the block and move to the

right 0.600". This is th center of the hole marked

"G". Lock the table.

- Mount a dial indicator on the "X" axis as

before. Preset the indicator to 0.500.

- Drill a hole 1/2" deep with a "Q" drill

bit. This will break through into the 1/4" hole,

this is OK. Tap the hole with a 3/8-24 tap. Finish with a

bottom tap if you have one.

- Drill the two 3/16 holes as you did in the Main Block.

Drill until the holes break through into the 1/4"

hole.

- Remove the block and chamfer the holes.

- Place the block on it's side in the vise. Drill and tap

the hole marked "D". Drill with the larger bit

first then through with the tap size bit. Just as done

previously.

- Remove the block from the vise and set it back in with

the marked side up. Make sure at least 1/4" of the

block is above the vise jaws.

- Mill out the 0.225 x 0.975 area above the dovetail.

- Using a 3/16" end mill, cut a slot 0200" wide

by 0.070" deep. For roughing the dovetail.

- Use a small triangular file that has been safed on one

side to cut the 60° angle on each side of the dovetail.

Keep the file flat on the bottom of the groove. Test the

fit of the dovetail to your Test Indicator to make sure

it fits snugly yet smoothly.

- Cut the two slots using a 0.020" slotting saw or a

hobby razor saw. The slot in the front has to be cut all

the way from top to bottom. The height of the slot on the

side is not critical, be sure to material at the top to

act as a spring.

Spindle

- Mount the 1/2" by 1.875" piece of CRS in the

lathe chuck with 1" protruding from the chuck.

- Face the end of the workpiece.

- Turn the .375" and the .250" diameters shown on

the drawing.

- Cut a slight 45° chamfer end and the two shoulders that

were created.

- Remove the workpiece from the chuck and make a scribe

mark on the workpiece 0.500" below the .375"

portion.

- Place the piece back in the chuck with the unturned

portion sticking out. Make sure the scribe mark is

outside of the chuck by at least 1/16".

- Turn to 0.250" up to the scribe mark.

- Turn to 0.246" up to about 0.174 from the shoulder.

This will be the threaded portion of the spindle.

- Cut a 1/4-20 thread on the spindle shaft. Use the Spindle

Block as a thread depth gauge.

- Trim the spindle to length and chamfer the end of the

thread with the 60° threading tool.

- By chucking on the 3/8" diameter. It is possible to

clean-up the 1/2" diameter using a cutting tool or a

file.

Fine Adjust Screw

- Mount the 1/2" x 2.5" piece of CRS in the lathe

chuck and face the end square and clean.

- Drill a small center hole if you plan to use the

tailstock while turning this piece.

- Extend the piece out of the chuck so that at least

1.75" is protruding from the chuck.

- Make sure the piece is running as true as possible, tap

with a hammer if necessary while tightening the chuck.

- Carefully cut the diameter to 0.375" - 0.372"

up to the chuck jaws.

- Turn the 0.250 diameter portion of the screw.

- Cut the threads at 24 TPI as close to the chuck as you

safely can. Use the included 3/8-24 nut as a thread

gauge.

- When the thread is finished, chamfer the right end of the

thread with the threading tool.

- Either cut off the piece in the lathe or remove the piece

and cutoff with a hacksaw in a bench vise (make sure you

grip the waste side with the bench vise).

- Place the piece back in the lathe by chucking on the

1/4" diameter end.

- Dress the cutoff end to length and chamfer the threads.

- Do not drill the 1/16 hole yet, that will be done at

final assembly.

Knob

- Chuck the 1" x 1.5" piece of CRS in the chuck

so that at least 3/4 to 7/8" is protruding.

- Face the end and drill the 1/4" hole 0.375"

deep.

- Turn the 0.500 diameter portion.

- Clean-up the 1" diameter so that it is bright and

smooth.

- Using a medium knurling tool, cut a knurl at least

0.2" wide.

- Using the thread cutting tool, chamfer the shoulder on

the threaded portion and the knurled portion.

- Cut off the part either on the lathe or at the bench.

- Place the piece back in the lathe chucking on the

1/2" diameter.

- 9. Face the cutoff side and cut a chamfer on the knurled

shoulder.

- Do not drill the 1/16" hole at this time.

Final Assembly

- Make sure all parts are clean and deburred. Graining the

aluminum parts using a 180 grit belt on the sander makes

a nice finish. Use WD-40 to prevent the belt from

"burning" the aluminum. It should come out

bright and shiny. The knob on the prototype was blued by

degreasing the part and heating it carefully with a

propane torch until the desired color was reached.

- Put the Fine Adjust Screw through the hole in the Main

Block. Place one or two paper washers on the 1/4"

shaft of the screw before pushing the Knob in place. The

paper will provide a small amount of clearance after the

knob is fixed in place. Push the knob on and clamp the

assembly in the milling vise so that the knob is pressed

tightly in place. Drill the 1/16" hole, and press in

the roll pin. Now remove the paper. The Fine Adjust Screw

should rotate smoothly.

- Face off and chamfer the ends of all four pieces of drill

rod that were supplied.

- Clean-up the 1/4" hole that goes from top to bottom

on the Holder Block with a hand held 1/4" drill bit.

Slide on of the 1/4" drill rods into the hole. Apply

a small amount of Loc-Tight to the inside of the

3/16" holes and to one end of each of the 3/16"

drill rods. Push the two 3/16" rods into the holes.

Clean off the excess Loc-Tight from the outside of the

holes and rods. Push the Main Block over the pins and

screw the fine adjust so the the Main Block is about

1/4" from the Holder Block. Remove the 1/4"

drill rod from the hole in the Holder Block and set the

assembly aside for the Loc-Tight to dry.

- Screw the Spindle lightly into the Spindle Block. Push

the two 1/4" drill rods into the block until the

ends are flush with the block. The best way to tighten

the spindle without marring it is to lock the spindle in

a collet and turn the assembly until it is tight enough.

- Press the Shear-Loc knobs on the socket head screws by

holding the screws lightly in a drill chuck (on a drill

press on tailstock of the lathe), placing the knob on the

screw, then pressing the knob on using the force of the

quill or tailstock.

- Using the 1/4" washer supplied, screw the 1/4"

screw into the top of the Main Block.

- Screw the 6-32 screw into the bottom of the main block.

- Using the supplied #8 washer, screw the 8-32 screw into

the side of the holder.

- Slide the Main Block and Holder assembly onto the Main

Rods and you are finished.

Aligning a rotary table

Appendix A

To build this project you should make sure you have access to

the following:

- Tap sizes #6-32, #8-32, 1/4-20, 3/8-24

- Drill bit sizes 1/16, #36, #29, 11/64, 3/16, #7, 15/64,

1/4, #F, and #Q

- Center drills #1 and #2

- Counter sink for chamfering.

- End mills 1/2" for general milling, 3/16 for cutting

slot for dovetail.

- Reamers of 3/16" and 1/4" would be helpful but

are not necessary.

- Small triangular file with one side safe.

- Test Indicator you wish to use for fitting dovetail.

- Dial Indicator with at least 1" of travel.

- Lathe

- Milling machine or milling attachment for lathe.

Appendix B

This is the list of materials supplied with the kit:

Quantity Size Material Used in this part

1 1.25 x 1.875 x 0.5 6061 Alum. Main Block

1 1.25 x 0.75 x 0.5 6061 Alum. Holder Block

1 1 x 1.625 x 0.5 6061 Alum. Spindle Block

1 1" dia. x 1.5 12L14 CRS Knob

1 0.5" dia. x 1.875 12L14 CRS Spindle

1 0.5" dia. x 2.5 12L14 CRS Fine adjust screw

2 0.188 x 1.375 Drill Rod Fine adjust rods

2 0.250 x 3.875 Drill Rod Main rods

1 8-32 x 1/2 SHCS* Indicator dovetail lock

1 #8 Shear-Loc Knob Indicator dovetail lock

1 #8 Washer Stainless Indicator dovetail lock

1 6-32 x 1/4 SHCS* Fine adjust lock

1 #6 Shear-Loc Knob Fine adjust lock

1 1/4-20 x 1/2 SHCS* Course adjust lock

1 1/4 Shear-Loc Knob Course adjust lock

1 1/4" Washer Stainless Course adjust lock

1 1/16 x 3/8 Roll Pin Steel Knob Retainer

1 3/8-24 nut Steel Gauge for cutting

fine feed screw

* Socket Head Cap Screw

Appendix C

Download Adobe Acrobat

Version of drawing (43K)